The Benefits of Using "Cut-to-Size", Semi-Finished Silver Sheets, Discs & Shapes in Manufacturing Silverware

Candlesticks, Menoras, trays & goblets begin their lives as a “silver sheet” which is then processed by pressing, spinning, soldering, etc.

In order to streamline and shorten processes, manufacturers will purchase the raw material in a shape closest to that of the final product.

Some examples:

Cups – start as a disk shape and go through a “deep drawing” or spinning process.

Oval trays – start as an oval sheet and will be pressed in a press.

Candlestick arms – start as a half-arm layout, and go through a process of pressing / cutting and soldering.

Other shapes – start as sheets adapted to the size of the product for maximum utilization of the sheet.

Advantages to the manufacturer:

The wastage in production will decrease by 30% -40% à as a result, raw material consumption will decrease by the same percentage à which will impact manufacturers’ cash flow.

The recycling process will become unnecessary or be reduced dramatically, which will reduce cost.

When buying the silver from manufacturers who specialize in production of semi-finished raw materials,

quality is much higher than manufacturing “in-house”.

This semi-finished raw material is uniform and regular therefore having fewer disqualifications during production, resulting in shorter production time & lower cost.

The work on the final polishing stage is easier due to the improved surface quality.

In addition, the labor prices of discs, ovals, and shapes are lower than buying raw sheets and cutting at the factory due to the huge wastage/depreciation.

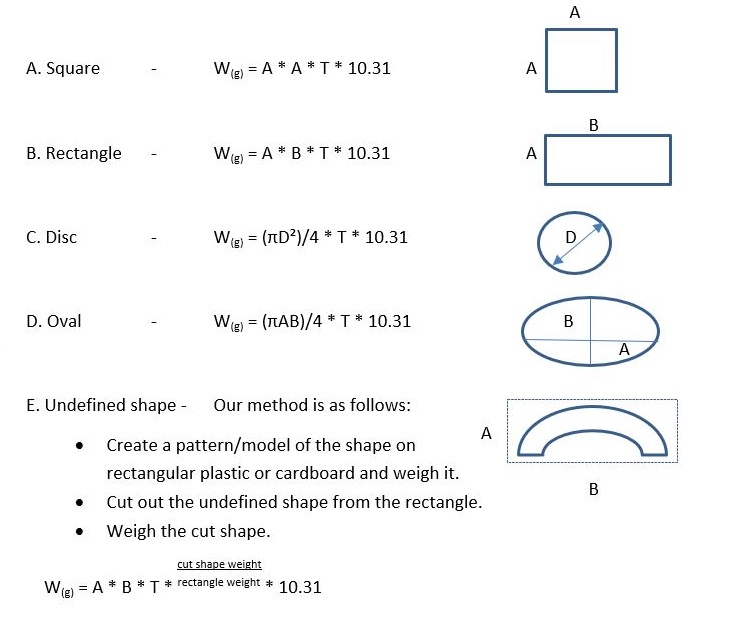

Weight Calculation of Sterling Silver Parts (925)

For your convenience, see below our preferred method of weight calculation of Sterling Silver parts.

Important: Lengths are in centimeters; “W” refers to weight in grams; “T” refers to sheet thickness in centimeters.

Summary of the advantages:

- Reduced amount of silver required for production.

- Cash flow improvement.

- Less polishing work and better surfaces quality.

- Saving on labor time.

- Fast production.

Recommendation:

Based on years of experience of working with La-Met Spa. (http://www.lametag.it/) from Italy, who use a state-of-the-art CNC that can cut any shape for semi-finished silver items

– This is definitely our recommendation.

Ami Gur

A.G. Metals Ltd.