ICP – Using ICP for Precious Metals Assaying

ICP stands for Inductively Coupled Plasma, which is a common analytical technique used in the precious metals industry to determine the concentrations of various elements in a sample of metal.

The ICP instrument uses an argon plasma to excite the atoms in the sample, causing them to emit characteristic wavelengths of light. This light is then detected and analyzed to determine the concentration of various elements present in the sample.

ICP is particularly useful for precious metals assaying because it is capable of analyzing a wide range of elements simultaneously, including trace elements that can be difficult to detect by other means. This is important in the precious metals industry, where even small variations in the composition of a metal can have a significant impact on its value.

In addition to its analytical capabilities, ICP is also a relatively fast and reliable technique, making it a popular choice for assaying precious metals. It is commonly used in the analysis of gold, silver, platinum, and other precious metals, as well as in the analysis of ores and other raw materials used in their production.

Components of the ICP instrument:

- Sample Introduction System: This is the part of the ICP instrument that is responsible for introducing the sample into the plasma. The sample is typically introduced in the form of a liquid solution or a fine powder. The sample introduction system can be either a pneumatic nebulizer or a laser ablation system.

- Plasma Torch: The plasma torch is where the sample is ionized and excited. The torch generates a high-temperature plasma by passing an inert gas (usually argon) through a radio frequency coil. The plasma torch typically operates at temperatures of up to 10,000 K.

- Optical System: The optical system is responsible for detecting the light emitted by the excited ions in the plasma. The emitted light is separated into its component wavelengths by a diffraction grating or a prism and detected by a photomultiplier tube. The intensity of the emitted light at each wavelength is proportional to the concentration of the corresponding element in the sample.

- Spectrometer: The spectrometer is the part of the instrument that is responsible for measuring the intensity of the emitted light at each wavelength. The most common type of spectrometer used in ICP instruments is the echelle spectrometer, which is capable of high-resolution measurements over a wide spectral range.

- Detector: The detector is responsible for converting the emitted light into an electrical signal that can be processed by the instrument’s computer. The most common type of detector used in ICP instruments is the photomultiplier tube, which amplifies the signal by converting the emitted photons into electrons.

- Data Processing and Control System: The data processing and control system is the computer that controls the instrument and processes the data obtained from the detector. The system typically includes software that allows the user to select the elements to be measured, calibrate the instrument, and analyze the data obtained from the sample.

Duration of an ICP analysis

The length of time required for the ICP process can vary depending on a number of factors, such as the type of sample being analyzed and the number of elements that need to be measured.

Generally, the ICP analysis itself takes only a few minutes per sample, but there are additional steps involved in preparing the sample for analysis that can add to the overall processing time. For example, the sample may need to be dissolved in acid and then filtered to remove any impurities before it can be introduced into the ICP instrument.

In addition, some samples may require multiple measurements to obtain an accurate reading, or may need to be analyzed multiple times to ensure consistency and repeatability of the results.

Overall, the time required for the ICP process can range from a few minutes to several hours, depending on the specific requirements of the analysis. However, ICP is generally considered a fast and efficient technique for elemental analysis, especially when compared to other traditional analytical methods such as fire assay or wet chemical methods.

Analyzing a wide range of elements simultaneously with ICP

ICP is capable of analyzing a wide range of elements simultaneously because it uses a plasma that can excite a large number of different types of atoms in the sample.

When a sample is introduced into the ICP instrument, it is first vaporized and then atomized into a fine mist. This mist is then introduced into the argon plasma, where the atoms are excited by the high temperatures and energy levels present in the plasma.

As the excited atoms return to their ground state, they emit characteristic wavelengths of light that are detected by the instrument. Each element emits light at specific wavelengths, which allows the ICP to distinguish between different elements in the sample.

By analyzing the different wavelengths of light emitted by the atoms in the sample, the ICP instrument can determine the concentrations of a wide range of elements simultaneously, even in trace amounts. This makes ICP a powerful tool for analyzing the composition of complex samples, such as those found in the precious metals industry.

There are several other traditional analytical methods that have been used for elemental analysis in the precious metals industry, including:

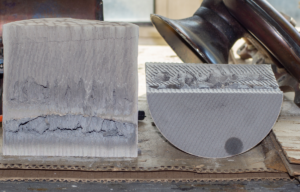

Fire Assay: This is one of the oldest and most widely used methods for the analysis of precious metals, particularly gold and silver. It involves heating a sample of the metal to a high temperature in the presence of fluxing agents and other reagents, which separates the precious metals from other components in the sample.

Wet Chemical Methods: These methods involve the use of chemical reagents to dissolve or react with the components in a sample, allowing the different elements to be separated and analyzed. Examples of wet chemical methods include gravimetric analysis, titration, and colorimetric analysis.

X-ray Fluorescence (XRF): This is a non-destructive analytical technique that uses X-rays to excite the atoms in a sample, causing them to emit characteristic wavelengths of radiation that can be detected and analyzed to determine the elemental composition of the sample.

Atomic Absorption Spectroscopy (AAS): This is a technique that uses light absorption to measure the concentration of specific elements in a sample. It involves passing a beam of light through the sample, and measuring the amount of light absorbed by the atoms of the element being analyzed.

Laser-induced breakdown spectroscopy (LIBS): A potent non-destructive analytical technique used for material detection and characterization. The process involves focusing a highly energetic laser pulse onto the surface of a solid or liquid, or within a sample volume of a liquid, gas, or aerosolized particles. As a result, a microplasma is generated, containing excited molecular and atomic species from the bulk sample, along with ablated particulates. These excited-state species emit light with distinct wavelengths, which can be collected using a spectrometer and transmitted to a computer. The uniqueness of each element’s emission spectrum enables the detection of all elements with LIBS.

While these traditional analytical methods have been widely used in the past, many of them have limitations in terms of accuracy, sensitivity, and speed compared to modern techniques like ICP. However, they are still sometimes used for specific applications or in cases where ICP is not practical or available.