Pyrometallurgy vs. Hydrometallurgy in Precious Metals Refining

In the realm of precious metals refining, two prominent methodologies stand out: pyrometallurgy and hydrometallurgy. Each approach offers distinct advantages and applications, shaping the landscape of the refining industry. Let’s delve into the nuances of these processes and their respective roles in extracting valuable metals like gold, silver, and platinum.

Pyrometallurgy: Harnessing Heat and Chemical Transformations

Pyrometallurgy relies on high temperatures to extract metals from their ores or concentrates. The process involves smelting or roasting the raw material in a furnace, where heat triggers chemical transformations, separating the metal from impurities. Crucially, pyrometallurgy is well-suited for ores with high metal content and stable mineral compositions.

In precious metals refining, pyrometallurgical methods are commonly employed for materials like gold doré, which contain relatively high concentrations of gold and silver. Through smelting, the doré undergoes intense heat treatment, causing the precious metals to melt and separate from other elements. Subsequent refining steps, such as cupellation or electrolysis, further purify the metals to achieve the desired purity levels.

Hydrometallurgy: Unlocking Metals with Solvent Solutions

Hydrometallurgy, in contrast, utilizes aqueous solutions to dissolve and recover metals from ores or concentrates. This approach is particularly effective for low-grade ores or complex mineral compositions where direct smelting may not be feasible. Hydrometallurgical processes typically involve leaching, where the ore is exposed to specific chemical solutions that selectively dissolve the target metals.

In precious metals refining, hydrometallurgy finds application in extracting gold and silver from low-grade ores or secondary sources such as electronic waste or tailings. Through techniques like cyanidation or thiosulfate leaching, gold is leached from the ore into a solution, which is then processed to recover the precious metal. Similarly, silver can be extracted using processes like silver nitrate leaching or cyanide leaching.

Comparative Analysis: Advantages and Considerations

While both pyrometallurgy and hydrometallurgy offer effective means of precious metals refining, they present distinct advantages and considerations:

Resource Flexibility: Pyrometallurgy is well-suited for ores with high metal content and stable mineral compositions, while hydrometallurgy offers versatility in treating low-grade ores or complex mineral matrices.

Energy Consumption: Pyrometallurgical processes typically require significant energy inputs due to high-temperature operations, whereas hydrometallurgy may consume less energy but may involve longer processing times.

Environmental Impact: Hydrometallurgy generally produces fewer emissions compared to pyrometallurgy, making it a preferred choice from an environmental perspective. However, hydrometallurgical processes may generate acidic or toxic by-products, necessitating proper waste management.

Cost Considerations: The cost of pyrometallurgy versus hydrometallurgy can vary depending on factors such as energy prices, ore characteristics, and process complexity. In some cases, hydrometallurgical routes may offer cost savings, especially for treating low-grade ores.

Conclusion: Leveraging Techniques for Optimal Results

In conclusion, both pyrometallurgy and hydrometallurgy play crucial roles in the precious metals refining industry, offering complementary solutions for extracting valuable metals from diverse ore sources. The choice between these methodologies depends on factors such as ore characteristics, environmental considerations, energy requirements, and economic feasibility.

By understanding the distinctions between pyrometallurgy and hydrometallurgy, refining facilities can optimize their processes to achieve efficient metal recovery while minimizing environmental impact and operating costs. Ultimately, the judicious application of these techniques contributes to the sustainable and responsible management of precious metal resources in the global market.

Harnessing the Power of Diamond Testers in Precious Metals Scrap Dealing

Harnessing the Power of Diamond Testers in Precious Metals Scrap Dealing In the competitive and intricate world of precious metals scrap dealing, tools that enhance

Professional Diamond Tester

Professional Diamond Tester, Gem Tester Pen Portable Electronic Diamond Tester Tool for Jewelry Jade Ruby Stone About this item This is a

GemOro Auracle Pen Probe

GemOro Auracle Pen Probe | Plug & Play Universal Replacement for AGT1 AGT3 Digital Gold & Platinum Testers | Precision Tool with Expert Professional Reading

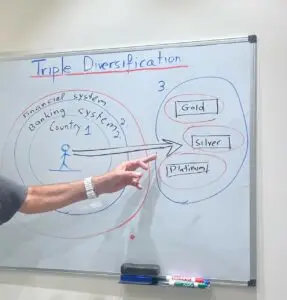

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking In the realm of physical investments, diversifying one’s portfolio is often associated with the acquisition

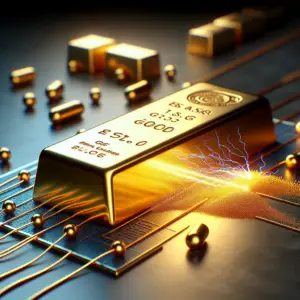

Electrical Conductivity of Precious Metals

SummaryThis article explores the electrical conductivity of precious metals and their alloys, focusing on its measurement in Siemens per meter and variations across different materials.