Revolutionizing the Precious Metal Industry with XRF Analysis

Precious metals, such as gold, silver, platinum, palladium, rhodium and iridium, are highly valued for their rarity and unique properties. These metals are often used in jewelry, electronics, auto catalysts and other high-tech applications, making them an important commodity in global trade. To determine the value of these precious metals, it is essential to know their elemental composition accurately. X-ray fluorescence (XRF) is a powerful analytical technique that can be used to determine the elemental composition of materials, including precious metals.

XRF is a non-destructive and relatively quick analytical technique. This makes it a popular choice for precious metal assay, where accuracy and speed are essential. The XRF technique works by emitting X-rays that excite the electrons in the atoms of the sample. As the electrons relax, they emit characteristic X-ray radiation that is detected by the instrument. The intensity of the X-rays is proportional to the concentration of the elements in the sample.

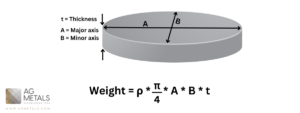

Before using XRF for precious metal assay, it is essential to prepare the sample carefully. The sample must be clean and free of any contamination that could interfere with the analysis. Any coatings or dirt should be removed, and for some materials, the sample should be ground to a fine powder. This ensures that the X-rays emitted by the instrument will penetrate the sample and accurately measure its elemental composition.

Once the sample is prepared, the XRF instrument must be calibrated using a set of standard samples with known concentrations of the elements of interest. The calibration curve generated from this process is used to calculate the concentration of the elements in the unknown sample. The calibration process is critical to the accuracy of the analysis. Therefore, it is essential to use high-quality calibration samples that accurately represent the composition of the samples being analyzed.

Most XRFs instruments are equipped with built in pre-calibrate modes which are suitable for specific groups of metals or applications. For example, the “Niton XL3 goldd+” has few modes such as: “Mining“, “Precious Metal”, “General Metals”, and “Electronic metals”, which make it easier to operate.

After calibration, the prepared sample is loaded into the sample chamber of the XRF instrument. Depending on the instrument, the sample may need to be pressed into a pellet or placed into a cup. Once the sample is loaded, the XRF instrument is turned on, and the analysis begins. Both with handheld and stationary XRF, it is also possible to just assay any part/metals on the surface (without any preparations) to get a good idea of the material content.

The XRF instrument generates a spectrum of the detected X-rays, which is used to determine the concentration of the elements in the sample. The results can be displayed as a table or graph, and the concentration of each element can be calculated from the intensity of its X-ray signal using the calibration curve.

The accuracy of the results obtained from XRF analysis is dependent on the quality of the sample preparation and the calibration of the instrument. Therefore, it is essential to follow the proper sample preparation and calibration procedures to ensure accurate and precise measurements of the concentration of precious metals in a sample. XRFs (mostly handheld) become a necessity tool for anyone dealing in metal recycling both for lab assay as well as for fast sorting of metal scrap. Another advantage is that the XRF assay can identify some of the impurities that may affect the value of the goods (for example: an ingot that contains precious metals with some hazardous materials such as cadmium, bismuth or lead, will have lower value due to higher refining costs).

In conclusion, X-ray fluorescence (XRF) is an effective and efficient analytical technique for precious metal assay. The use of XRF in precious metal assay is particularly valuable in situations where the sample is rare or valuable, and destructive testing is not desirable. By following the proper sample preparation and calibration procedures, accurate and precise measurements of the concentration of precious metals in a sample can be obtained quickly and non-destructively. XRF is a valuable tool for the precious metal industry, providing critical information that enables informed decision-making and enhances the value of these precious resources.

Since the XRF assay is very fast compared to other chemical lab techniques, refiners use the XRF assay as a tool for pre-valuing the scrap to perform pre-payments.