Distinguishing Between Casted and Stamped Bullion Bars: Applications and Considerations

When considering investments in gold or silver, understandin g the variances between casted and stamped bullion bars is essential. These differences extend beyond mere appearance, influencing their applications and suitability for various purposes.

g the variances between casted and stamped bullion bars is essential. These differences extend beyond mere appearance, influencing their applications and suitability for various purposes.

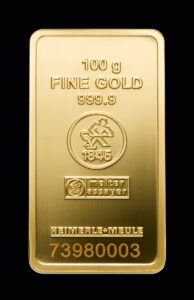

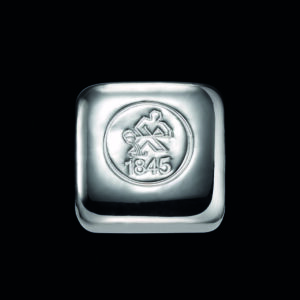

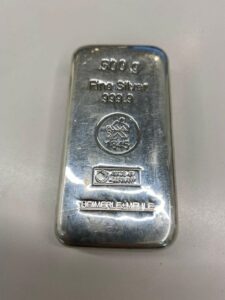

Manufacturing Distinctions Casted bullion bars undergo a production process involving the pouring of molten gold into a mold. This method often yields bars with irregular textures and shapes due to the inherent nature of casting. In contrast, stamped bullion bars are crafted by pressing or stamping a blank piece of gold with precise designs and markings. The result is a more uniform appearance with clearly defined edges and surfaces.

Cost Considerations While manufacturing costs for both types of bars can be similar, they may vary depending on factors such as design complexity and size. However, in general, the cost difference between casted and stamped bars might not be significant. Institutions and individual investors often consider factors beyond manufacturing costs, such as the perceived value and market demand for each type.

Weight Varieties and Market Preferences Stamped bullion bars are typically available in smaller weight denominations, ranging from 1 gram to 100 grams, making them popular among individual investors and collectors for their affordability and ease of storage. In contrast, casted bars are found in a wider range of weights, including larger denominations exceeding 1000 grams. These larger casted ingots, weighing up to 30000 grams, are often preferred by institutions, such as banks, or industrial manufacturers for their efficiency in handling bulk transactions and storage.

Industrial Applications Casted ingots weighing over 1000 grams find extensive use in industrial applications, particularly in sectors like jewelry making and silverware production. The larger ingots provide a stable and consistent source of raw material, ensuring uniformity and quality across production batches. Additionally, the cost-effectiveness of purchasing larger ingots in bulk and their versatility in customization further enhance their appeal to industrial users.

Conclusion In conclusion, the choice between casted and stamped bullion bars involves careful consideration of various factors, including manufacturing processes, cost implications, weight varieties, and intended applications. While stamped bars may be favored for individual investments due to their standardized appearance and smaller denominations, casted ingots weighing over 1000 grams hold a crucial role in institutional and industrial settings. Their efficiency, precision, cost-effectiveness, and customizability make them indispensable assets in the intricate world of gold and silver handling.

By understanding these nuances, investors can make informed decisions tailored to their specific needs and preferences, whether they seek tangible assets for personal investment or raw materials for industrial production.

Harnessing the Power of Diamond Testers in Precious Metals Scrap Dealing

Harnessing the Power of Diamond Testers in Precious Metals Scrap Dealing In the competitive and intricate world of precious metals scrap dealing, tools that enhance

Professional Diamond Tester

Professional Diamond Tester, Gem Tester Pen Portable Electronic Diamond Tester Tool for Jewelry Jade Ruby Stone About this item This is a

GemOro Auracle Pen Probe

GemOro Auracle Pen Probe | Plug & Play Universal Replacement for AGT1 AGT3 Digital Gold & Platinum Testers | Precision Tool with Expert Professional Reading

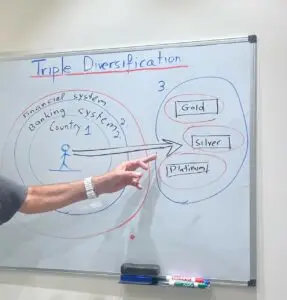

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking

https://youtu.be/kv7K83a8ku4

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking In the realm of physical investments, diversifying one’s portfolio is often associated with the acquisition

Electrical Conductivity of Precious Metals

SummaryThis article explores the electrical conductivity of precious metals and their alloys, focusing on its measurement in Siemens per meter and variations across different materials.