ARE YOU FROM UK or USA ? ARE YOU INVESTING in GOLD or SILVER?

TAKE A LOOK BELOW AND CLICK TO LEARM ABOUT GOLDBROKER

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!!!!!!!!!!!!

!!!!

Unveiling the Crucible of Civilization : A Comprehensive Guide to Smelting

Introduction: Smelting, an ancient alchemy of fire and metal, has been pivotal in shaping human civilization since its dawn. From the Bronze Age to the modern era, smelting has enabled the transformation of raw ores into refined metals, laying the foundation for technological advancement and economic prosperity. In this article, we delve into the intricate process of smelting, its historical significance, contemporary applications, environmental concerns, and the enduring legacy of pyrometallurgy.

Understanding Smelting: Smelting is the process of extracting metal from its ore through the application of heat and chemical reduction. This method involves heating the ore to high temperatures in a furnace, where it undergoes a series of chemical reactions, ultimately resulting in the separation of the desired metal from its impurities. The key components of smelting include the ore, fluxes (substances that promote the fusion of impurities), and fuel sources, such as charcoal or coke, which provide the heat necessary for the reaction.

Historical Significance: The origins of smelting can be traced back to ancient civilizations, where early metallurgists discovered the transformative power of fire on metal ores. One of the most notable advancements in smelting occurred during the Bronze Age, when humans learned to alloy copper with tin, ushering in an era of unprecedented technological progress. The development of iron smelting further revolutionized warfare, agriculture, and trade, shaping the course of human history.

Process of Smelting: The process of smelting varies depending on the type of metal and ore being processed. However, the basic steps typically involve:

- Ore Preparation: The raw ore is crushed and ground into smaller particles to increase its surface area and facilitate chemical reactions.

- Roasting: In some cases, the ore is roasted to remove sulfur and other volatile impurities, making it more amenable to smelting.

- Smelting: The crushed ore is placed in a furnace along with fluxes and fuel, where it is heated to temperatures exceeding the metal’s melting point.

- Separation: As the ore melts, the metal separates from the gangue (unwanted materials) and sinks to the bottom of the furnace.

- Refining: The molten metal is then refined to remove any remaining impurities, producing a pure metal ingot ready for use.

Contemporary Applications: In the modern era, smelting remains integral to various industries, including mining, metallurgy, and manufacturing. Metals extracted through smelting, such as iron, copper, and aluminum, serve as essential building blocks for infrastructure, machinery, and consumer goods. Moreover, advancements in smelting technology have enabled the production of high-performance alloys tailored to specific applications, from aerospace components to electronic devices.

Environmental Concerns: While smelting has propelled human progress, it also poses significant environmental challenges. The combustion of fossil fuels during smelting releases greenhouse gases and air pollutants, contributing to climate change and respiratory illnesses. Additionally, smelting operations generate hazardous waste streams containing heavy metals and toxic chemicals, posing risks to ecosystems and human health. To mitigate these impacts, regulatory measures, technological innovations, and sustainable practices are essential to minimize emissions and enhance resource efficiency.

Pyrometallurgy: A Legacy of Innovation: Pyrometallurgy, the branch of metallurgy focused on high-temperature processes like smelting, embodies humanity’s ingenuity in harnessing the power of fire. From ancient kilns to modern blast furnaces, pyrometallurgical techniques have evolved to meet the demands of an ever-changing world. Innovations in furnace design, fuel utilization, and process optimization have made smelting more efficient, cost-effective, and environmentally sustainable. As we continue to push the boundaries of metallurgical science, the legacy of pyrometallurgy endures as a testament to human creativity and perseverance.

Conclusion: Smelting stands as a testament to humanity’s ability to harness nature’s elements to forge a brighter future. From its humble origins in ancient hearths to the towering furnaces of the industrial age, smelting has shaped the course of human civilization, enabling progress and innovation across generations. As we confront the environmental challenges of the 21st century, the principles of sustainability, efficiency, and responsibility must guide the future of smelting, ensuring that this ancient art continues to enrich and empower societies for millennia to come.

***If you are interested on Melting VS Smelting press VS

Are you looking to diversify your crypto into gold? Look down into BULLIONSTER!!!!!!!

Harnessing the Power of Diamond Testers in Precious Metals Scrap Dealing

Harnessing the Power of Diamond Testers in Precious Metals Scrap Dealing In the competitive and intricate world of precious metals scrap dealing, tools that enhance

Professional Diamond Tester

Professional Diamond Tester, Gem Tester Pen Portable Electronic Diamond Tester Tool for Jewelry Jade Ruby Stone About this item This is

GemOro Auracle Pen Probe

GemOro Auracle Pen Probe | Plug & Play Universal Replacement for AGT1 AGT3 Digital Gold & Platinum Testers | Precision Tool with Expert Professional Reading

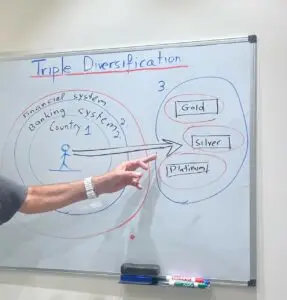

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking

Triple Diversification: Expanding Your Investment Strategy Beyond Borders and Banking In the realm of physical investments, diversifying one’s portfolio is often associated with the acquisition

Electrical Conductivity of Precious Metals

SummaryThis article explores the electrical conductivity of precious metals and their alloys, focusing on its measurement in Siemens per meter and variations across different materials.